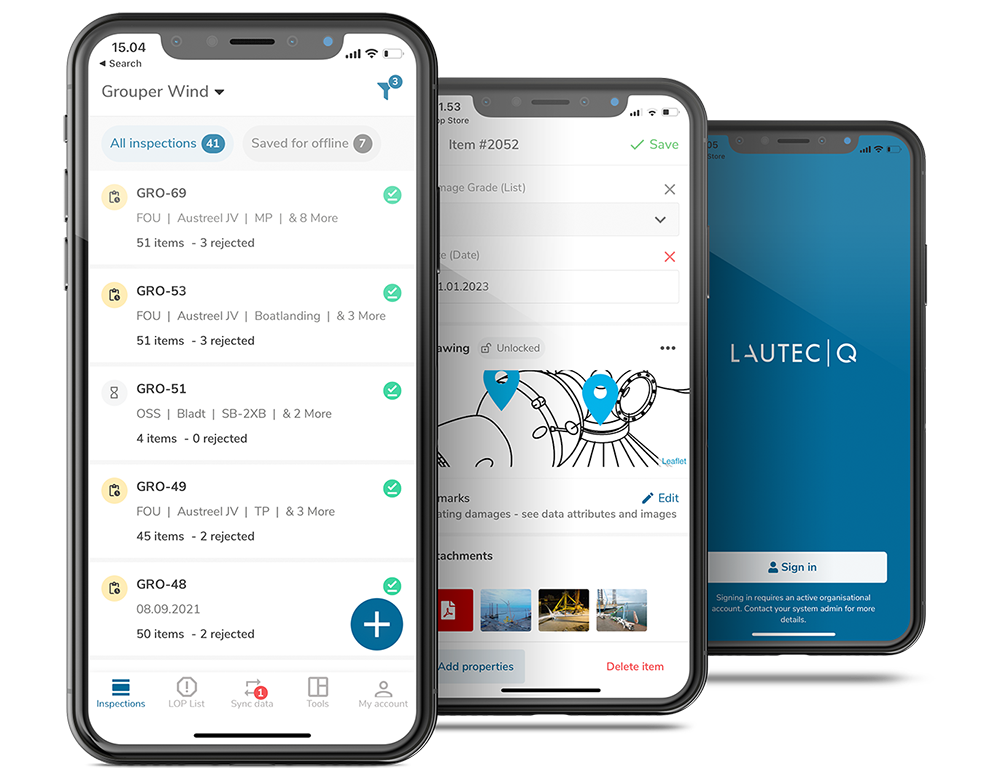

Quality Inspections

Wind Power Inspection Tool

Our Q system is a web and mobile app-based digital inspection tool designed for wind power projects. It digitalizes any process for site inspections, shop surveillance, and walk-downs, including the registration and follow-up on non-conformities.